- High Pressure Laminate / Compact Density Fiberboard

- Medium And High Density Fiberboard

- Chemical Resistant Board

- Fireproof Board

-

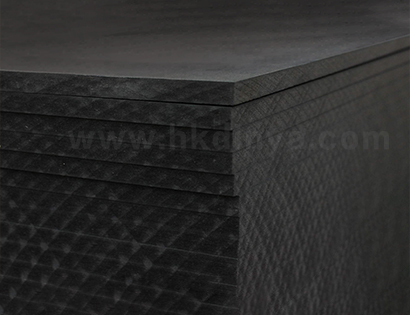

High Pressure Laminate

The base material of the High Pressure Laminate is black, white, light green and brown. It is made of more than 120 sheets of fine imported kraft paper impregnated with phenolic resin and imported decorative colored paper with special treatment under heat and high-pressure to form a double-faced decor high-density sheet of laminate. The thickness can be adjusted according to the number of kraft paper. The thickness can be made from 1.5mm to 30mm.

Please inquire for more sizes

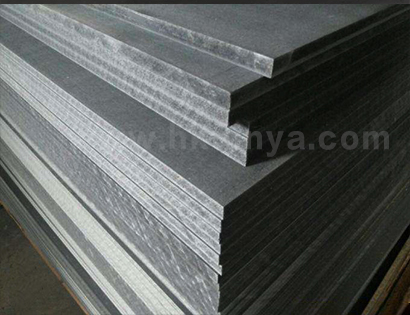

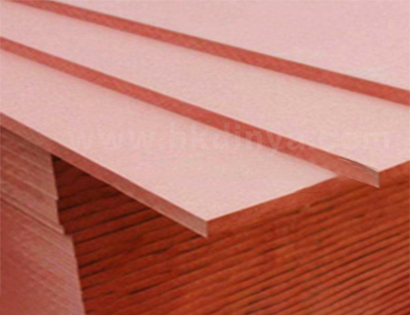

Compact Density Fiberboard

Compact Density Fiberboard is artificial board made of wood fiber and urea-formaldehyde resin. According to its density, it is divided into high density, medium density, low density boards, It has certain waterproof and wear-resistant properties. It replaces moisture-proof boards and particle boards as a upgrade material for toilet partition selection.

Density: 750/830/950/1050/1200/1400

Various thickness/density can be customized

-

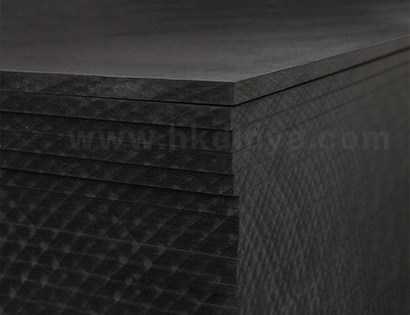

Medium And High Density Fiberboard

Medium And High Density Fiberboard is a kind of artificial board made of wood or plant fibers by mechanical separation and chemical treatment, mixed with adhesives and waterproofing agents, and then formed by high temperature and high pressure. It is an ideal artificial board for making furniture. The structure of Medium And High Density Fiberboard is more uniform than that of natural wood, and it also avoids the problems of decay, moth-eaten, etc. At the same time, it has less expansion and contraction and is easy to process. Because the surface of the Medium And High Density Fiberboard is smooth, it is easy to paste various finishes, which can make the finished furniture more beautiful. In terms of bending strength and impact strength, it is better than particle board.

1220*2440 -

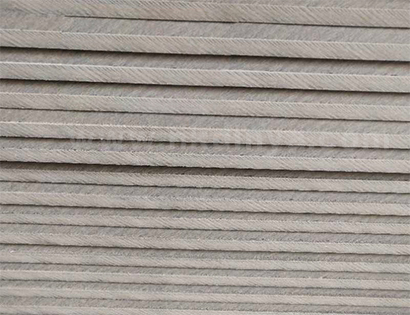

Fireproof Board

Also known as flame-retardant board, flame-retardant plywood, flame-retardant plywood, etc., it is a three-layered or more layer made from wood logs or wood planed into small wooden cubes, and the wood chips are subjected to flame retardant treatment and then glued with adhesive Layered plywood is usually made of odd layers of wood chips, and the fiber directions of adjacent layers of wood chips are glued perpendicular to each other.

Density 660, 750, 800, 880, 980, 1080, 1150, 1250, 1350

Zhenying Wood Industry Co., Ltd. was established in December 2009. The office address is located in Yunfu, a young and charming city. The company mainly trades in the processing of compact density fiberboard core and fireproof board.we are engaged in the producing,processing,developing of medium and high density fiberboard,and also the sales of board.Since its inception, the company has always adhered to the principle of people-oriented, integrity management. Guided by the market,zhenying did the research and development of new products,and produced the fiberboard substrate material series of 700-1500 density .High-density fiberboard can be developed according to customer requirements, which can replace compact panels.zhenying adheres to the business spirit of "people-oriented, customer first" , advocates the corporate culture of "integrity, unity, dedication, hard work", strives to provide customers with quality products and sound after-sales service, and constantly open up the market to the world.

7 key stages of advanced technology process

Diya Group

DIYA(Group)

Diya Group

public number

Nanjiangkou Town. Yunfu City. Guangdong. China

official website

WeChat Public Number

Contact Us

8 managements

1. The on-line infrared moisture content detector is used to monitor the moisture content of the fiber during the whole production process, ensuring stable fiber moisture content, and monitoring of multiple online broad embryos to ensure stable weight and uniform density of the product;

2. The hot pressing process applies two control methods of thickness and pressure to achieve the product profile density distribution’s stability and adjustability;

3. Monitor the thickness of the board online;

4. First sanding then cutting process, avoiding the thin side problem of the product;

5. Accurate and stable PLC program control across the entire line;

6. High-performance environmentally-friendly waterproof non-toxic glue, low formaldehyde content, low water absorption thickness expansion rate;

7. Continuous online monitoring system and strict product inspection system;

8. Strict craft discipline, quality spirit of excellence.

Product Display

1. Wood chip selection and water system guarantees the same chip size and stable moisture content;

2. With Sufoma’s Defiberator BM1111/15-12, fiber separation more uniform, delicate and stable;

3. High-performance two-stage drying system and temperature automatic PID adjustment ensure the stability of fiber moisture content;

4. Mesto’s Uniformer and process guarantees the surface density of fiber mat in even quality;

5. Using the domestic first-class D-SWPM company’s multi-layer presses and technology to ensure the stable physical and mechanical properties of the product;

6. High-precision SANDA MACHINERY wide-format sander to ensure smooth and surface quality;

7. ANDA MACHINERY's high-precision automatic cutting machine enables cutting precision up to +1mm

Address: Room 2116, CITIC Plaza, No. 233 Tianhe North Road, Tianhe District, Guangzhou

Copyright© 2020 Diya Group All Rights Reserved 粤ICP备20052248号